Until recently the correct answer was:

- Flow Injection for serial assays and research

- Sequential Injection for monitoring of industrial and environmental processes,

because Fi offers high sampling frequency and versatility that is valuable for research

purposes, while SI offers robustness, reliability and low sample and reagent

consumption.

However, this is no longer entirely correct, since the recent advances in miniaturization, microfluidic manipulations and software development, empowered SI methodology making it more versatile and faster,as shown on this example.

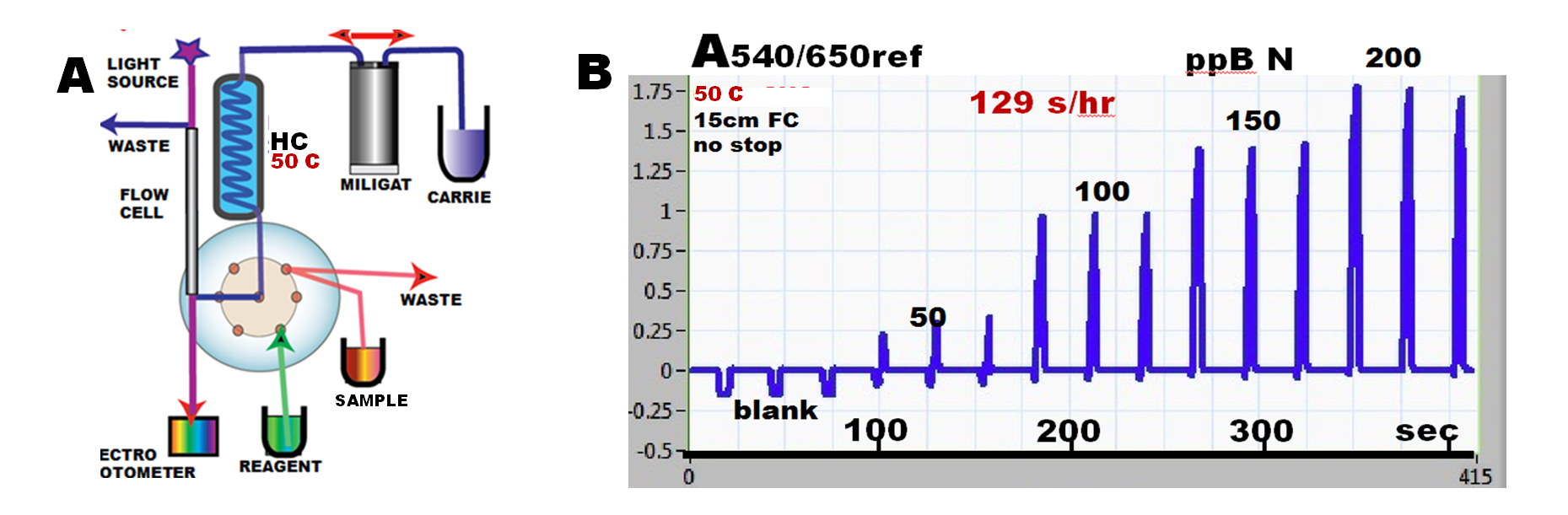

A single line miniSIA-1 instrument (A) comprises a multiposition valve that integrates microfluidics with flow trough sample inlet, flow trough cell (shown here configured for spectrophotometry) and a holding coil (HC) that serves as the reactor that is thermo stated. The instrument typically uses DI water as a carrier, and processes sample and reagent volumes in the range of 20 to 150 microliters. The heart of the system is miliGAT pump that is bidirectional and synchronously refilling, capable of delivering uninterrupted flow within the range of 1 to 1000 microliters/ second.

Sequential Injection or Flow Injection?

2.1.1.A.

In this configuration a single reagent method, such as assay of nitrite, using Grie’s reagent (2.2.17.) can be run at a sampling frequency comparable to the same FI protocol (B) The same applies to more complex assays such as phosphate (2.2.25.) or nitrate (2.2.19.). Actually the same miniSIA-1 system can be used for simultaneous assay of nitrite and nitrate (2.2.22.) or phosphate and silicate (2.2.33.B.) a task impossible with a single channel FI setup.

There is, however, ( as always) a caveat: while SIA is well suited for one and two reagent6 assays, more complex assays still are best run in FI configuration. But this also may change, as more complex assays will become automated using two line miniSIA-2 systems (2.2.42.A.).