Lab-on-valve and System Configuration

2.2.4.

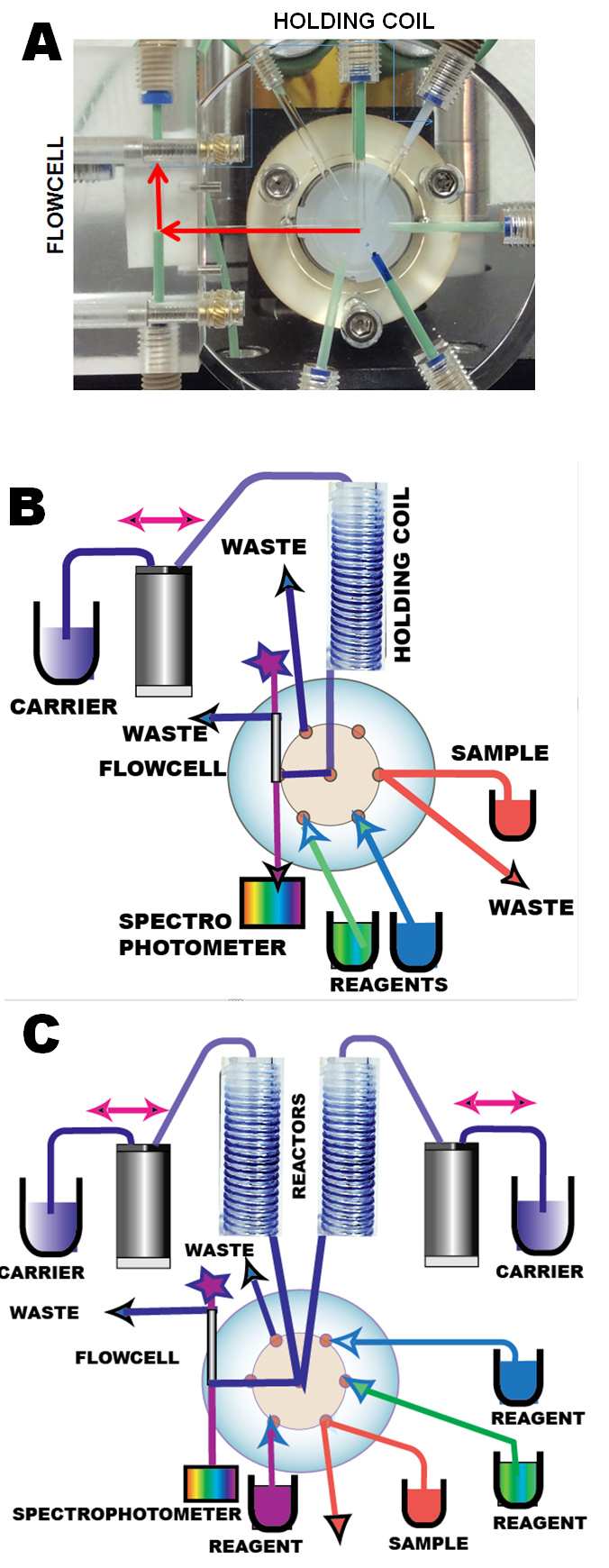

The principal features of design of the lab-on-valve (A) module are the short channel between the central port and detector, and the long holding coil, situated upstream from the multiposition valve. In this flow geometry the concentration gradients of sample and reagent are formed within the holding coil, and remain largely unaffected during the short passage from the point of injection to detection. Therefore in the miniaturized SI system, dispersion is controlled by programming the flow and by selecting volumes of sample and reagents injected into and retrieved from the holding coil, rather then be changing the length of mixing coils, as it is done in Flow Injection.

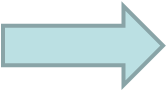

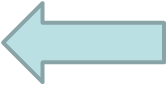

The miniaturized SI instrument can be configured as:

- single line with one pump and one holding coil (B)

- two lines with two pumps and two holding coils (C)

The traditional single line configuration will accommodate majority of reagent based assays. The two line instrument will handle assays that use more than two reagents, or column separations, or gas diffusion methods, since the second pump supports a wide variety of configurations.

The mutual dispersion of sample and reagent zones is in the following sections visualized and evaluated by injecting a dye, into a colorless carrier stream. As the zone of the dye, which simulates a sample is aspirated into the holding coil, it forms a parabolic profile, because the central streamline moves twice as fast as mean flow velocity (0.2.2.). As a result, the concentration gradient expands axially as it advances upstream into the holding coil. Radial mixing is enhanced, by increasing amplitude of the flow reversal into the holding coil, where the flow path is distorted by coiling and by other obstacles ( Section 2.3.4.). The progress of axial and radial dispersion can be estimated from the changing shape of recorded peaks that change from asymmetrical to Gaussian shape (Section 0.3.4.), as the sample zones trough the increasing number of mixing stages.

When performing the real life assays, samples to be analyzed are mixed with reagents by this mechanism, since sample and reagent concentration gradients mutually penetrate each other in axial direction, and are blended radially as they move upstream into the holding coil. To optimize this process, sequence of sample and reagent their volumes, flow rates and geometry of the flow path must be carefully chosen, based on reaction sequences and reagent compatibility.